Software interfacesIntuitive and ergonomic for your comfort!

The performance of your test bench or production machine is also defined by its ease of use.

This is why our teams of developers strive to make software easy to use thanks to intuitive and ergonomic interfaces, called Human Machine Interfaces (HMI).

LF Technologies offers you a turnkey service, from the study of your needs to the tailor-made graphic design of your user interface. We define together its functionalities (user actions, screen sequence, etc.) and its graphic elements according to your graphic charter.

Multi-screen version

The control console can be easily configured by users and used via various media (control panel, tablet, PC, smartphone). A simple click is enough to launch a test. The interface allows you to see the status of your test in real time.

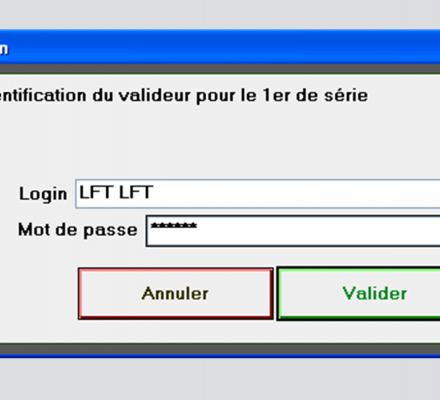

Access management by login

All the software designed by our teams is equipped with an administrator interface to manage user accounts and their access rights. The database is thus entirely secure thanks to the integration of login and password.

Access management by RFID / Traceability of operations

Our test benches and modular production machines can be interfaced with a database in SQL format (time stamps, user identifiers, product references, serial numbers, etc.). They are then equipped with RFID operator identification. This identification is done quickly, by simply presenting the badge to the reader. The operation does not require a validation button or a password.

The request for operator identification after a manual operation such as assembly, cutting or transfer is programmed in the test and assembly sequencer (database).

This function is blocking, and the sequencer cannot continue to run until the operator has identified himself with a valid badge.

Automatic control mode :

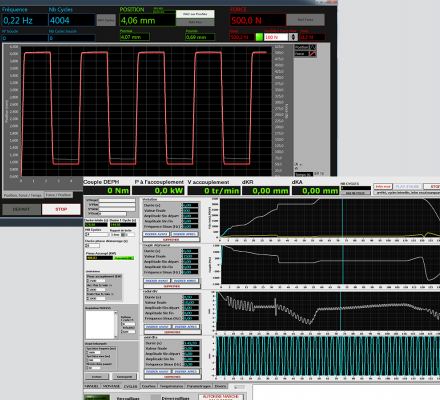

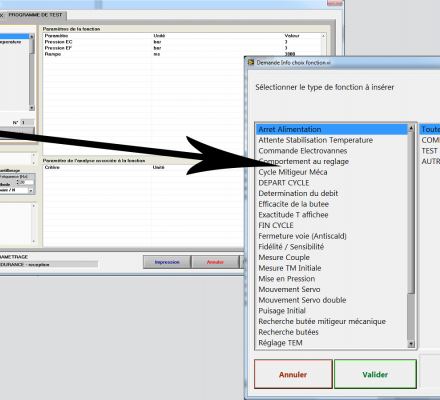

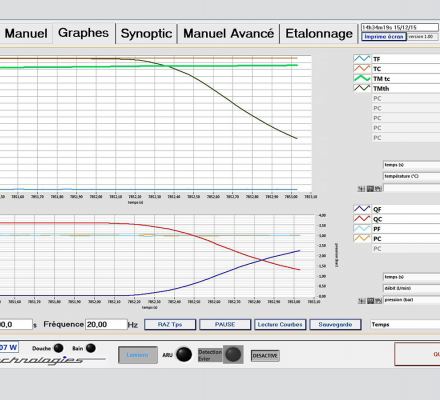

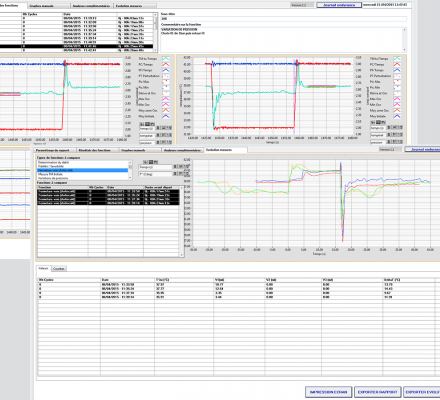

The software manages the execution of an automatic program, consisting of a sequence of simple functions that can be parameterized. During the execution of these functions, information (curves, results, comments) is displayed in the test information insert.

At the same time, the screen continuously displays in real time the measurements of pressure, flow, temperature, number of cycles, force, displacement, etc.

During an automatic test, all measurements are systematically saved in a file, in text format. This file can be opened by the automatic analysis and reporting module.

The programming of these test cycles is intuitive: it consists of a programmable sequence of simple parameters dedicated to classic test functions.

Our benches are delivered with a set of pre-programmed and parameterized test procedures.

Manual control mode

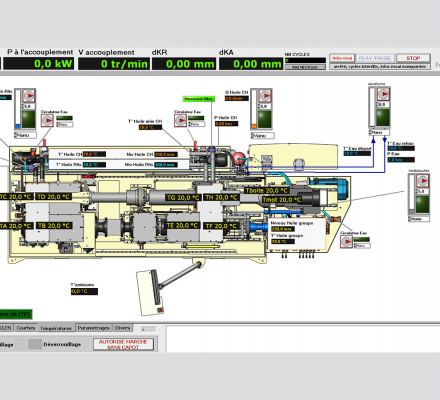

In addition to the automatic control mode, our interfaces also have a so-called "manual" control mode, which allows you to act manually on the actuators and basic functions of the bench, to launch the execution of a unitary program function, and to visualize all the measurements on an active synoptic.

Curve display module

The graphical module on our software displays the evolution of a set of measurements, in manual mode or in automatic test execution.

Measurement calibration module

All measurements made by the machine can be checked with the calibration module, by comparison with an external standard measurement. Measurement faults are saved to allow automatic linearity correction.

Automatic analysis and reporting module

In order to ensure traceability of operations, measurements are automatically saved and can be exported in different formats (Word, Excel, HTML or PDF) for easy reading and analysis.